ELECTROBOT software solutions

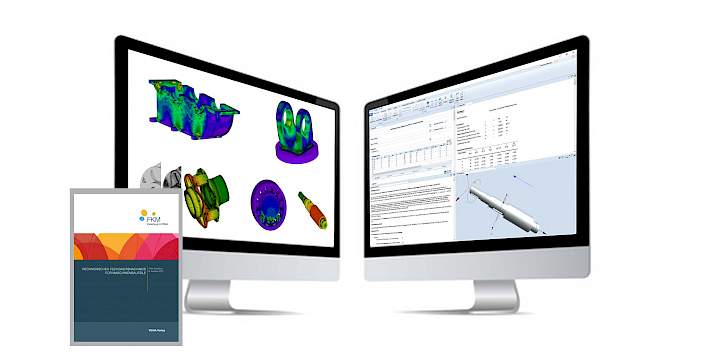

Document, proof, inform

User interface for engineers

Everyone knows it: If you need specific information to solve a design task, it is usually not directly accessible. With the ELECTROBOT explorer environment, a wealth of answers are available centrally in one place: Calculation libraries, formulas, material data, or manufacturer and product information. The modern and intuitive design guarantees quick orientation.

Material data & strength assessment

safety through fast information

The arithmetical proof of strength for machine components according to the FKM guideline presents challenges for users owing to the cross-part applicability, for example. Produce proofs of power by the directive for welded and non-welded components in a short space of time with ELECTROBOT technology. In addition, access an extensive material database and expand it individually.

Screw connections, bolts & pins

Safety in screw calculation

Use ELECTROBOT as a powerful tool to design and optimize screw connections functionally and safely according to guidelines VDI 2230, Eurocode 3, or DIN.

Shafts, axles, hubs

Optimize and design drive shafts

Use ELECTROBOT to optimize, evaluate and prove the safety of shafts and shaft-hub-connections.

Roller & Plane Bearings, Linear Technology

Calculate bearing life

ELECTROBOT allows you to calculate loads of different bearing types. Determine service life and required boundary conditions of lubrication and maintenance.

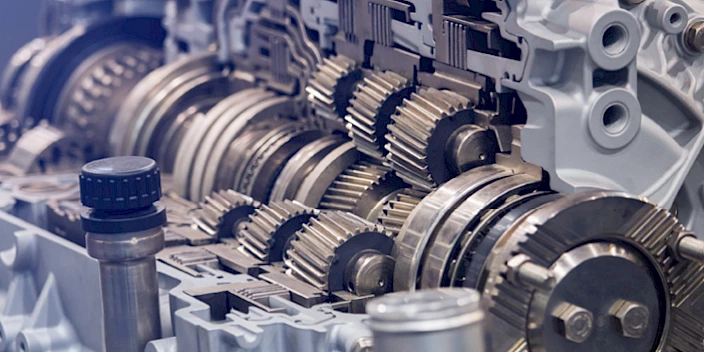

Gearing, gears, drive technology

Calculate powerful drive systems

Different gear shapes are calculated and verified based on DIN, EN, AGMA, and ISO regulations. Gear modules for assemblies allow additional geometry, mass, and installation space optimizations. The micro-geometry of gears is also optimized with specially created ELECTROBOT modules. For new and further optimized competitive drive solutions.

Welded connections, soldered & bonded joints

Optimal design of permanent connections

In addition to the design of brazed and riveted joints, the focus is on weld seam calculations and their safety verification. Depending on the requirements profile, this is based on the FKM guideline, Eurocode 3, or the DVS data sheets. If adhesive bonding methods are a vital connection, the calculation accesses an adhesive database with characteristic values from numerous manufacturers.

Apparatuses, pipelines, sealings

Optimal results under pressure

The new ELECTROBOT process library supports numerous tasks related to pressure loss calculations, wall thickness determination, and flange and pressure vessel calculations. Based on the standard-compliant fundamentals according to DIN, EN, and AD data sheets, these requirements are quickly solved and automatically documented.

Contact us

+1 4092910738

Contact person

Send us a message

Questions? Want to receive a free trial?

Find the right contact person for your inquiry.

support@electrobotusa.com